What are the raw materials for the production of compressed coal?

Maybe you have heard the name of compressed coal or even used this product in your use. Compressed coal, as its name suggests, is one of the types of coal. This product is richer than ordinary coals and has many advantages. This type of coal is also called Chinese coal, industrial coal, and mold coal. The production process and raw materials for the production of compressed coal also have differences with ordinary coal. This product is created by using several raw materials and combining and compressing them.

Currently, compressed coal is considered a very good alternative to traditional coal, and its consumption is increasing day by day. This coal has not harmed the environment and its high heat and durability are also significant. Compressed coal is a product without odor and gas, and it is economical and suitable.

Although this type of coal is of high quality and has the efficiency you want, however, choosing the most suitable and high-quality raw materials for the production of compressed coal plays a significant role in increasing the quality of the obtained product and is one of the most important concerns of business owners. Coal production works.

In fact, in order for these people to be able to produce the best compressed coal they want, they must pay particular attention to the quality of the raw materials. Otherwise, they will not achieve their desired goal by going through the production process.

In this article, we will provide information about raw materials for the production of compressed coal, and we will review and review the types of these products and their production process. So if you are looking for more information in this field, stay with us.

All types of compressed coal

According to a general classification, compacted coal can be placed in two main types, which are: compacted coal of sawdust and compacted coal of coal soil. Each of these products has its own characteristics, and their materials and compositions and production process are also slightly different from each other.

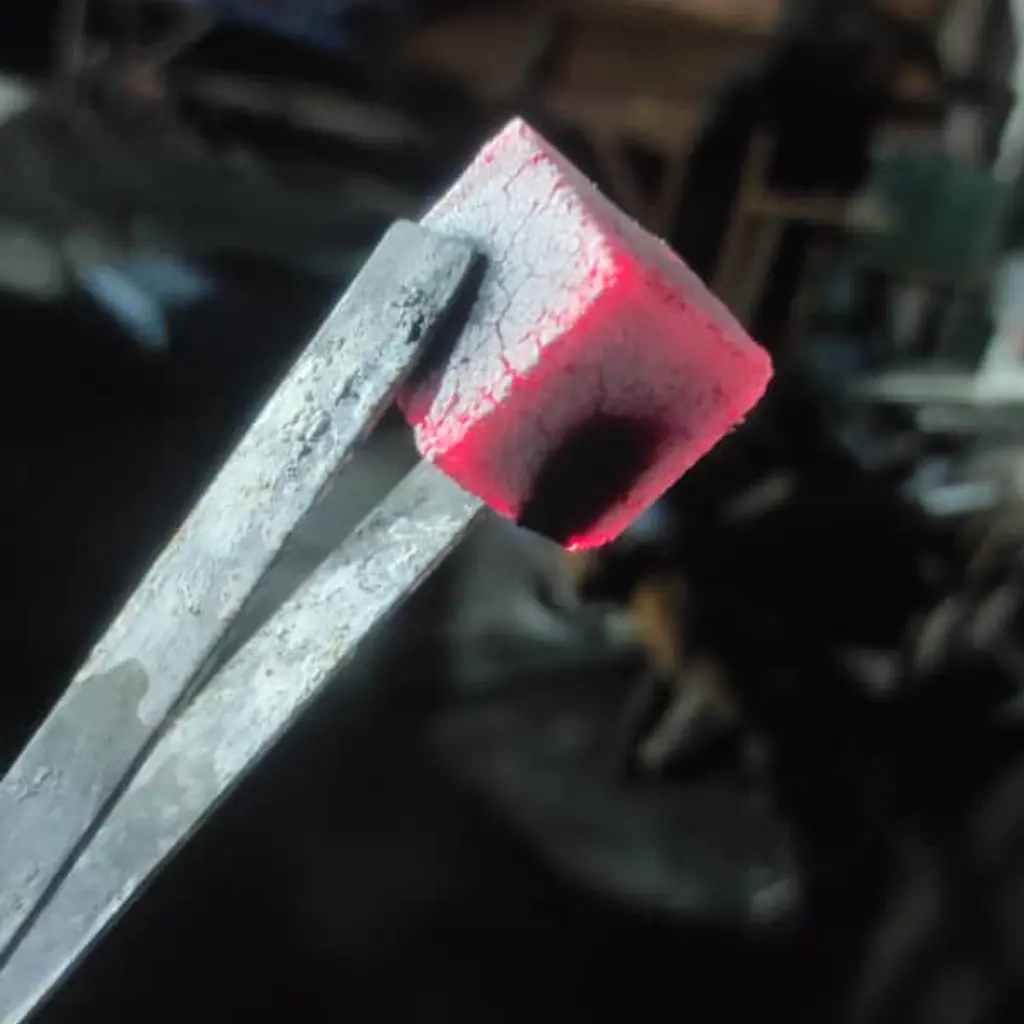

You can use any of these products in specific uses and industries. However, the appearance of these two products is not much different from each other and you can find both of them in hexagonal, quadrangular, cube, cylindrical cube, etc.

Raw materials and method of producing sawdust charcoal

Producers need materials and compounds such as walnut shell, sawdust, wood waste, etc. to make compressed coals of sawdust type. Each of these materials has special characteristics and special points and conditions should be considered for their selection.

For example, sawdust is one of the most important raw materials for the production of compressed coal, which plays a significant role in the quality of the final coal produced. For this reason, it must have adequate humidity. The amount of moisture required for sawdust should not be high or low.

On the other hand, sawdust should have a suitable size and this size should be selected based on the capacity of the compact coal production machine. Paying attention to the type of sawdust is also very important. Normally, walnut, fir, beech, forest wood, plantain wood, etc. are used to make suitable sawdust as the main raw materials for the production of compressed coal.

Walnut shell for the production of sawdust charcoal

Another raw material for the production of sawdust compressed coal is walnut shell, which contains things such as amino acids, steroids, alkaloids, proteins, vitamins, etc. Walnut skin is used to produce high quality sawdust charcoal.

To choose this material, they should be careful about the freshness or oldness of the walnut skin, its quality and percentage of purity, its volume and quantity, and consider the durability and shelf life, impurities, thinness or the thickness of the walnut skin. After providing the raw materials for the production of compressed coal, they can start the process of making this product.

To implement this process, all the raw materials provided are combined with the help of a device called a belt extruder. The main reason for using this device is that it has a high production speed, and on the other hand, they can use traditional furnaces to produce this charcoal.

Wood waste for the production of sawdust charcoal

Wood scraps used to produce sawdust charcoal are sourced from furniture factories and other wood products to ensure the final quality of the charcoal to hand. After making the raw materials for the production of charcoal, the prepared materials are placed in the furnace to prepare charcoal.

In the normal state of these compounds, 70% of soil, 20% of walnut shell and 10% of wood waste are used.

What are the raw materials for the production of compressed coal?

Raw materials and method of coal production, coal soil

The required raw materials and the production method of compacted coal are slightly different from the production method and the materials and compounds used in the production process of sawdust coal. In such a way that manufacturers use materials such as coal chips to make charcoal soil. Charcoal chips produced in the traditional way.

In this method, after collecting small coals, the process of grinding them is done and the required materials are compressed. In other words, in order to produce charcoal, charcoal is first made into powder and the charcoal powder is passed through a strainer.

By doing this process, all the impurities and extra materials are separated from the powders. After combining and mixing these ingredients, they are molded and the dough is compressed. In this way, it can be said that one of the most important differences between the method of producing sawdust coal and carbon coal or coal dust is that in the process of producing coal dust, the materials and compounds provided after being collected and compressed are not placed in the furnace to be baked. . Because they are placed inside the oven once.

Raw materials for the production of compressed coal, coal soil

Other raw materials for the production of compressed coal are charcoal soil, citrus fruits, coconut carbon, pistachio carbon, and oak. In the usual case, producers use citrus fruits to make charcoal soil in order to provide grilled charcoal. And pistachio carbon, coconut and oak carbon are used to produce hookah charcoal.

In most cases, hookah charcoal manufacturers produce lumps, cubes or squares, and consider small sizes and dimensions for it. The appearance of this product is also remarkable and has a special beauty. For this reason, pistachio charcoal, coconut charcoal and oak are widely used in coffee houses. Because the attractive appearance of these products helps to attract more customers and increases the desire to use them.

See also: What kind of coal is used in different countries?

Advantages of coal compacted coal soil

The quality of this type of coal is also suitable and does not create sparks. The use of the most suitable raw materials for the production of compacted charcoal also ensures that this product does not have any waste and does not create ash and soot after burning and creating a flame.

The price is right

On the other hand, these products can produce high flame for a long time. You should also be aware of the fact that compact coals have several special advantages compared to sawdust coal. One of the most important advantages is that the devices needed to make these products have a more reasonable price than the equipment needed to produce sawdust charcoal.

Less pollution

Also, pay attention to the fact that compacted coal of the sawdust type does not cause any damage to the environment and does not cause any special pollution. However, sawdust may be spread around your workshop and cause pollution. The presence of this pollution and the spread of soil particles in the work environment may cause harm and danger to the breathing of human forces.

On the other hand, sawdust coal producing devices make a lot of noise, which can be considered as a kind of noise pollution. You will not face this problem in the process of charcoal production. Because the devices that make these products do not cause much noise pollution.

to be economical

In the coal production process, low energy consumption electrical equipment is used. For this reason and with the help of these tools and equipment, you will also help to save electricity in your workshop. The amount of gas used to produce sawdust charcoal is much more than coal dust. Because high temperature furnaces must be used. You will need less manpower and labor to produce charcoal soil than to produce sawdust coal.

Result

Because of these advantages, there are many uses of compressed coal and the amount of consumption of these products is increasing day by day. In the present situation, charcoal is used in industrial and workshop purposes and various jobs in addition to cooking and baking kebabs.

Fars blazing charcoal is the provider of compressed coal with the best quality and guaranteed price, please contact us for more information and order. “blazing charcoal, the heat of life”.